TM5SDO2TFS Digital Output Safety Module (SLCv2)

This topic applies to an SLCv2 generation module (in a safety-related system with an SLC300 or SLC400 device). Which device generation is configured in your project is visible at the end of the short device description above the parameter grid (while the device is selected in the tree on the left).

Module type/safety-related fields of application

Output safety-related module, 2 safety-related output channels.

0.5 A rated output current, 1 A total rated current.

Output protection: thermal switch-off for over-current or short-circuit and integrated protection for switching inductive loads.

24 VDC rated voltage.

Schneider Electric safety-related modules can be used in safety-related applications according to:

-

EN ISO 13849, PL e

-

IEC 62061, SIL 3

-

IEC 61508, SIL 3

Group: Basic

Parameter: MinRequiredFWRev

|

Default value |

Basic Release |

|

Unit |

-/- |

|

Description |

This parameter is only relevant in case of implementing other firmware versions than the manufacturer-loaded version. To enter the operational state, the firmware version parameterized here or a newer version must be installed on the module.

The firmware version selected here is particularly important with regard to parameters or process data items that have been implemented with a particular firmware version. If the device you are currently working with has new parameters or process data items, the following applies: if MinRequiredFWRev is set to an incorrect value, either the SLC will not enter the operational run status or the new parameters/process data items will not be taken into account by the SLC. Refer to the hazard message below this table.

Further Information:

Information on newly added parameters or process data items can be found in the Release Notes you received with the firmware package. The Release Notes also describe how to determine the firmware version that is currently installed on the safety-related device. |

| WARNING | |

|---|---|

Parameter: Optional

|

Default value |

No |

|

Unit |

-/- |

|

Description |

The module can be configured as optional using this parameter. Optional modules do not have to be available (physically present or communicative), i.e., if an optional module is unavailable, this is not signaled by the Safety LogicController. This parameter does not influence the module signal or status data. |

|

Possible values |

|

The Optional parameter is a mechanism to scale your safety-related system for various configurations of your machine design. However, it may be the case that the module(s) that you have designated as optional may be required in some of your alternative machine configurations.

| WARNING | |

|---|---|

Parameter: DisableOSSD

|

Default value |

No |

|

Unit |

-/- |

|

Description |

This parameter can be used to disable the automatic testing of the output driver for each channel of the module. |

|

Possible values |

|

Group: SafetyResponseTime

The safety response time is the time between the arrival of the sensor signal on the input channel of a safety-related input module and the shut-off signal at the output channel of a safety-related module. For further and detailed background information, refer to the topic "Safety Response Time for SLCv2 " in the "Machine Expert – Safety - User Guide".

The parameters in this group influence the safety response time of the Safety Logic Controller system. The parameters SafeDataDuration and ToleratedPacketLoss in this group are only applied to the module if ManualConfiguration is set to 'Yes'.

Parameter: ManualConfiguration

|

Default value |

No |

|

Unit |

-/- |

|

Description |

Specifies whether the module uses its safety response time-relevant parameters (SafeDataDuration and ToleratedPacketLoss) or the values specified in the 'SafetyResponseTimeDefaults' parameter group of the Safety Logic Controller. Managing parameters per module optimizes the system to application-specific requirements regarding the safety response time. |

|

Parameter value |

|

Parameter: SafeDataDuration

|

Default value |

200 |

|

Value range Step size |

25...9,380 1 |

|

Unit |

100 µs |

|

Description |

This parameter influences the safety response time of the safety-related application. Specifies the maximum permissible time for data transmission from a safety-related producer to a consumer, that is, from an input module to the SLC, or from the SLC to an output module. Based on this parameter value and the value of the 'ToleratedPacketLoss' parameter (described below), and further module-specific processing times, the Safety Response Time (SRT) is calculated. Verify the SRT resulting from the parameter values entered here using the 'Response Time Calculator' dialog in Machine Expert – Safety (menu item 'Project > Response Time Calculator'). |

|

Value calculation |

The risk analysis you have performed for your safety-related application delivers the maximum allowed overall response time of the safety function and, as part of this, the safety function response time (SRT) of the signal chain. The SRT is composed of the following partial time values:

with

(including configured filter/delay times),

(including configured delay times),

This maximum SRT value is the basis for the calculation of the SafeDataDuration (SDD) and the ToleratedPacketLoss (TPL) value you must enter as the parameter value in the grid. From the allowed SRT, deduct the processing times of the safety-related input module (SPTi) and the output module (SPTo). The result is the total maximum permissible time for the safety-related data transmission on the complete safety-related path, i.e., from the input module to the output module. As the SafeDataDuration parameter relates to only one transmission path (input module -> SLC or SLC -> output module), you must divide the value by 2 to get the required value to be entered in the parameter grid. If a packet loss greater than 0 is tolerated, this must also be considered. The calculation equation is as follows:

With

|

Parameter: ToleratedPacketLoss

|

Default value |

1 |

|

Value range Step size |

0...10 1 |

|

Unit |

Data packets |

|

Description |

Specifies the maximum allowed number of lost packets during data transmission. The number of tolerated packet losses affects the safety response time. Based on this parameter value and the value of the 'SafeDataDuration' parameter, the Safety Response Time (SRT) of the system is calculated. Verify the SRT resulting from the parameter values entered here using the 'Response Time Calculator' dialog in Machine Expert – Safety (menu item 'Project > Response Time Calculator'). |

Group: SafeDigitalOutput01 and SafeDigitalOutput02

Parameter: AutoRestart

|

Default value |

No |

|

Unit |

-/- |

|

Description |

Activates or deactivates the automatic restart of the output of the module. |

|

Possible values |

NOTE:

In both cases, after a channel error has been detected in the module (and the source of the error has been removed or otherwise mitigated), the affected output must be deactivated and activated again by means of a positive edge of the release signal. |

Configuring an automatic restart can result in unintended implications for the safety-related system. It may be necessary to implement additional measures to avoid unintended consequences.

| WARNING | |

|---|---|

Process data items of the module

Purpose and use of process data items

Each module provides process data items (signals). Process data items can be:

-

I/O signals delivered from or written to a module terminal.

-

diagnostic signals for evaluating the status of input/output channels or the entire module.

-

control signals, for example, for enabling a channel or adjusting the module.

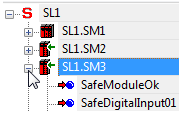

The available process data items of a module are listed under the module node in the tree on the left of the 'Devices' window. To display and use the process data items, expand the module node in the tree by clicking the '+' symbol.

Example

The module with the ID SL1.SM3 provides (among others) the diagnostic signal SafeModuleOK and the input signal SafeDigitalInput01.

From the devices tree, process data items can be inserted into the safety-related FBD/LD code by drag & drop (see following procedure). On insertion into the code, a standard (non-safety-related) or safety-related global variable is created (depending on the data type of the process data item).

Procedure: How to insert process data items into the code

-

Open the code worksheet where you want to insert the process data item and create/use the global variable assigned to it.

-

In the 'Devices' window, open the devices tree on the left and expand the module (tree node) which contains the process data item to be used.

-

Drag the process data item into the code worksheet. When releasing the mouse button, the 'Variable' dialog appears.

To insert a Boolean variable as a contact into the graphical code, hold the <CTRL> key down when releasing the mouse button after dragging the variable from the device terminal grid into the code worksheet.

-

In the 'Variable' dialog, a default name is proposed which is derived from the process data item name. Accept the proposed name, select an existing global variable, or declare a new global variable by entering a new 'Name', defining the 'Data Type' and selecting a 'Group'.

-

Confirm the 'Variable' dialog by clicking 'OK'.

The rectangle shape of the variable is now added to the cursor. It can be dropped at the desired position with a click. You can directly connect the variable to another object (e.g., a formal parameter as shown in the following example) or dropped at any free position.

Data direction depends on the signal type

Input signals can only be read and output signals can be written by the safety-related application.

Diagnostic signals can be used to evaluate and monitor the status of the safety-related module or individual I/O channels, for example. Therefore, global variables created for and assigned to diagnostic signals can be read by the application.

Control signals can be used to enable the module operation or to adjust/adapt the module for the present use case (for example, by setting a measurement range or a particular module behavior). The global variables created for and assigned to control signals can be written by the application, thus controlling the module.

Representation of the process data items in the devices tree:

|

Icon |

Signal type |

Access type |

|---|---|---|

|

Safety-related input signal or diagnostic signal. |

read |

|

Non-safety-related input signal (only available for the Safety Logic Controller). |

read |

|

Non-safety-related output signal (only available for the Safety Logic Controller) or control signal. |

write |

|

Safety-related output or control signal. |

write |

If a standard (non-safety-related) signal is connected to a physical input or output, the data type of the corresponding global variable must be modified from safety-related to standard (e.g., from SAFEBOOL to BOOL) to rule out an incorrect use of the signal in the code. The same applies if a safety-related signal is used only as standard signal in the code. Modifying the data type can either be done in the appropriate variables worksheet or using type converter functions.

| WARNING | |

|---|---|

In the following, the I/O, diagnostic and control signals of the present module are listed and described in the order they are listed in the devices tree.

SafeModuleOK

|

Description |

Indicates the status of the communication between the safety-related module and the Safety Logic Controller and therefore, from safety-related application perspective, the module status itself. |

|

Signal type |

Diagnostic |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be read by the safety-related application |

|

Possible values |

SAFEFALSE:

SAFETRUE:

|

Mandatory assignment validation for the SafeModuleOK data item:

The verification/validation of the assignment of each process data item to a global I/O variable is mandatory. This particularly applies to the SafeModuleOK process data item which is available for each safety-related module and indicates its status. As the SafeModuleOK data item cannot be written to, e.g., by applying a signal to a module input, the module to be verified must be physically removed from the TM5 bus. As a result, SafeModuleOK switches to SAFEFALSE and the assigned global I/O variable must follow. For further information on the steps to remove and reinsert a module, refer to the user manual of the module.

| WARNING | |

|---|---|

SafeDigitalOutputxx

|

Description |

Safety-related enable signal of the module, channel xx.

NOTE:

The single-channel signals SafeDigitalOutputxx cannot be used at the same time with the combined enable signal SafeDigitalOutputxxyy of the module. General Information Safety-related outputs can only be activated by the Safety Logic Controller (SLC). Depending on the setting in the respective safety-related TM5/TM7 output module, the non-safety-related controller must additionally enable the safety-related output (acknowledge the safety-related signal).

For that purpose, the 'User Parameters' editor of the SDO module in Logic Builder provides one

The

The enable signal may only control the process directly if it does not adversely affect the safety-related function. Refer to the first hazard message below this table.

NOTE:

In the Machine Expert – Safety 'Devices' window, the column 'LogicBuilder Variable' displays the name of the variable which has been mapped to the enable signal in the 'TM5 Module I/O Mapping' editor in Logic Builder. This representation must not be misinterpreted: Although the enable signal ('ChannelName'), the safety-related 'Variable' name, and the LogicBuilder variable are displayed in one row, the LogicBuilder variable cannot write the safety-related output. The LogicBuilder variable only agrees to the activation of the output. The physical activation of the output, however, can exclusively be initiated by the SLC. Confirmation of validity The validity of this output signal is confirmed by the related diagnostic signal SafeOutputOKxx. Depending on the results of the risk analysis you carried out for your application, the diagnostic signal must be evaluated each time the SafeDigitalOutputxx signal is used in the safety-related application. The value SAFEFALSE of the diagnostic signal indicates an invalid SafeDigitalOutputxx value. In this case, the SafeDigitalOutputxx signal must not be further used, processed, or evaluated in the safety-related application. Refer to the second hazard message below this table.

Further Information:

Refer to the topic "Monitoring/evaluating diagnostic information of the machine" for further information. Restart inhibit active When a restart inhibit is active for channel xx (parameter 'AutoStart = No'), the safety-related output remains in the defined safe-state after removing the safety request, or, in case of a module error, the cause of the error. This is to avoid an inadvertent machine/system restart. If the restart inhibit has been specified, a positive edge at the relating ReleaseOutputxx signal (see description below) is required to remove the inhibit and enable the machine/system to function. |

|

Signal type |

I/O signal |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be written by the safety-related application. The effect of the variable value depends on the setting of the CentralControl_DigitalOutput_xx module parameter in the Machine Expert application (see "Description" above). |

|

Possible values |

SAFETRUE:

SAFEFALSE:

|

|

Relevant module parameters |

In the parameter group with the same channel number xx:

The related parameter descriptions can be found above in this topic. In the Machine Expert application, 'User Parameters' of the output module:

|

| WARNING | |

|---|---|

| WARNING | |

|---|---|

SafeChannelOKxx (relating to enable signals)

|

Description |

Diagnostic signal which indicates the status of the safety-related output channel (enable signal). xx specifies the channel number. This diagnostic signal confirms the validity of the SafeOutputxx signal. Depending on the results of the risk analysis you carried out for your application, the diagnostic signal must be evaluated each time the SafeOutputxx signal is used in the safety-related application. The value SAFEFALSE of the diagnostic signal indicates an invalid SafeOutputxx value. In this case, the SafeOutputxx signal must not be further used, processed, or evaluated in the safety-related application. Refer to the hazard message below this table.

NOTE:

To detect error status conditions of modules/channels within your application, diagnostic signals must be evaluated in the safety-related code. A programming example and further information can be found in the topic "Monitoring/evaluating diagnostic information of the machine". |

|

Signal type |

Diagnostic signal |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be read by the safety-related application |

|

Possible values |

SAFEFALSE:

SAFETRUE:

NOTE:

Also observe the respective LED indicator(s) of the affected modules for the error indication. |

| WARNING | |

|---|---|

ReleaseOutputxx and ReleaseOutputxxyy

|

Description |

ReleaseOutputxx is the release signal for the single-channel enable signal SafeOutputxx. ReleaseOutputxxyy is the release signal for the two-channel enable signal SafeOutputxxyy, i.e., the combination of the output channels xx and yy. When a restart inhibit is active for channel xx/xxyy (parameter 'AutoStart = No'), the safety-related output remains in the defined safe-state after removing the safety request, or, in case of a module error, the cause of the error. This is to avoid an inadvertent machine/system restart. If the restart inhibit has been specified, a positive edge of the respective release signal is required to remove the inhibit and enable the machine/system to function. Resetting a diagnostic state and setting an output must not result in any hazards. In case of any doubt, reset the entire system instead of the single channel. Refer to the hazard message below this table.

Further Information:

Refer to the topic "Monitoring/evaluating diagnostic information of the machine" for further information and an application example.

NOTE:

If the safety-related module enters the defined safe-state and SafeModuleOK = SAFEFALSE, the ReleaseOutputxx/xxyy signal cannot be used to release the channel. Instead, the entire module must be restarted. Example: if input values exceed the allowed electrical maximum values as specified in the technical data of the device, the module must be restarted. |

|

Signal type |

Control signal |

|

Data type |

SAFEBOOL |

|

Access type |

Variable can be written by the safety-related application |

|

Possible values |

|

|

Relevant module parameters |

In the parameter groups with the same channel number xx/xxyy:

The related parameter descriptions can be found above in this topic. |

| WARNING | |

|---|---|