FB_HeatingControl - General Information

Task

The function block FB_HeatingControl monitors and controls heating systems.

This function block is the successor of the TemperatureControl_Easy function block which was available in the Packaging Library of SoMachine.

Description

The function block FB_HeatingControl is designed to monitor and control heating systems. This means that the output q_rAnalogOutput can only have values greater than or equal to zero.

The auto-tuning algorithm is based on the so-called relay method. With this method, the process is induced by oscillations. After the completion of three oscillations, the auto-tuning calculates a set of PID parameters.

Also refer to chapter Auto-Tuning (Heating).

It is important to ensure that the parameters are rational. There is no plausibility verification done by the function block.

| WARNING | |

|---|---|

Set the input i_xEnable to FALSE if an invalid process value is detected (for example if a temperature sensor is no longer connected).

Process temperatures must also be validated.

| WARNING | |

|---|---|

The process temperature is not taken into account in open loop operation. This is the case with i_xHold = TRUE or i_xManualMode = TRUE, and i_lrManualValue > 0.

Set the input i_xEnable to FALSE if an over-temperature is detected (for example, by setting an excessive value for i_lrManualValue during manual mode is active).

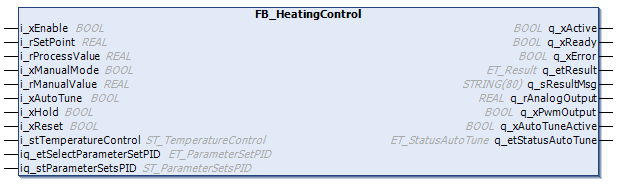

Interface

|

Input |

Data type |

Description |

|---|---|---|

|

i_xEnable |

BOOL |

TRUE: Enables function block and parameters are validated. FALSE: Disables function block and all outputs are set to 0 or FALSE. Active in all modes. |

|

i_rSetPoint |

REAL |

Temperature (in user-defined units) to be maintained by the system. Active in auto and auto-tuning mode. Range: i_stTemperatureControl.rSetPointLowLimit ≤ i_rSetPoint ≤ i_stTemperatureControl.rSetPointHighLimit Default value: 0 [user-defined temperature unit] |

|

i_rProcessValue |

REAL |

Process temperature value [user-defined temperature unit.] The process temperature value must be scaled outside the function block (for example, with the FB_Scaling of the Toolbox library). Active in auto and auto-tuning mode. |

|

i_xManualMode |

BOOL |

TRUE: Enables manual mode FALSE: Disables manual mode Active in manual mode. Only takes effect if q_etStatusAutoTune = ET_StatusAutoTune.Inactive. |

|

i_rManualValue |

REAL |

Manual mode PID output Active in manual mode. Range: i_stTemperatureControlr.PidLowLimit ≤ i_rManualValue ≤ i_stTemperatureControl.rPidHighLimit Default value: 0 |

|

i_xAutoTune |

BOOL |

Enables auto-tuning with a rising edge from FALSE to TRUE. A falling edge does not stop auto-tuning. Active in auto-tuning mode. Default value: FALSE |

|

i_xHold |

BOOL |

TRUE: Stops the internal PID calculation and holds the output q_rAnalogOutput at the present value. FALSE: Resumes the internal PID calculation. Default value: FALSE Only takes effect if q_etStatusAutoTune = ET_StatusAutoTune.Inactive AND i_xManualMode = FALSE. |

|

i_xReset |

BOOL |

Certain diagnostic messages can be reset using the input i_xReset. If a diagnostic message cannot be reset by a rising edge of i_xReset, verify and modify the parameter which causes the issue. Active in all modes. |

|

i_stTemperatureControl |

Includes various parameters needed for temperature control. |

|

In-/Output |

Data type |

Description |

|---|---|---|

|

iq_etSelectParameterSetPID |

It is possible to select one of the 5 PID parameter sets to influence the PID controller behavior. Each set includes different values for the PID parameters (rKp, rTn, rTv, rTd). |

|

|

iq_stParameterSetsPID |

Structure providing 5 different PID parameter sets. |

|

Output |

Data type |

Description |

|---|---|---|

|

q_xActive |

BOOL |

Indicates with TRUE that the program code is executing and that it must be executed in each cycle. |

|

q_xReady |

BOOL |

Indicates with TRUE that the POU is ready and can be controlled via its inputs according to its functionality. After the function block has been activated via a rising edge of i_xEnable, the output q_xReady is only set to TRUE if the function block can process instructions from the inputs. |

|

q_xError |

BOOL |

Indicates with TRUE that an error has been detected. For details, refer to q_etResult and q_etResultMsg. |

|

q_etResult |

Provides diagnostic and status information as an enumeration value. |

|

|

q_sResultMsg |

STRING [80] |

Provides additional diagnostic and status information as a text message. |

|

q_rAnalogOutput |

REAL |

Analog form (signal) of output or manual value (in manual mode). Range: i_stTemperatureControl.rPidLowLimit ≤ q_rAnalogOutput ≤ i_stTemperatureControl.rPidHighLimit |

|

q_xPwmOutput |

BOOL |

PWM signal according to the output q_rAnalogOutput. TRUE: Heating on FALSE: Heating off |

|

q_xAutoTuneActive |

BOOL |

TRUE: Auto-tuning active FALSE: Auto-tuning inactive |

|

q_etStatusAutoTune |

Current status of auto-tuning as an enumeration value. Default value: ET_StatusAutoTune.Inactive |

Diagnostic Messages

The following elements of ET_Result are used for q_etResult.

|

Name |

Data type |

Value |

Description |

|---|---|---|---|

|

Ok |

UDINT |

0 |

Operation completed successfully. |

|

SetPointOutOfRange |

UDINT |

300 |

i_rSetPoint < rSetPointLowLimit or i_rSetPoint > rSetPointHighLimit |

|

SetPointLowLimitOutOfRange |

UDINT |

301 |

rSetPointLowLimit < -100000 or rSetPointLowLimit > rSetPointHighLimit |

|

SetPointHighLimitOutOfRange |

UDINT |

302 |

rSetPointHighLimit > 100000 or rSetPointHighLimit < rSetPointLowLimit |

|

ControlModeOutOfRange |

UDINT |

303 |

Accepted control mode range: Refer to ET_ParameterSetPID. |

|

ManualValueInvalid |

UDINT |

304 |

i_rManualValue < rPidLowLimit or i_rManualValue > rPidHighLimit |

|

CycleTimeInvalid |

UDINT |

305 |

Calculated task cycle time must be greater than 0 and less than or equal to 10000 [ms]. |

|

DeadBandInvalid |

UDINT |

306 |

rDeadBand < 0 or rDeadBand > 100 |

|

PidParametersOutOfRange |

UDINT |

307 |

One or more PID parameters are out of range |

|

PidControllerIssue |

UDINT |

308 |

General issue from the internal PID controller |

|

PwmTimePeriodOutOfRange |

UDINT |

309 |

Value rPwmTimePeriod out of range or the value is less than the determined task cycle time. |

|

PidLowLimitOutOfRange |

UDINT |

310 |

rPidLowLimit < 0 or rPidLowLimit ≥rPidHighLimit |

|

PidHighLimitOutOfRange |

UDINT |

311 |

rPidHighLimit > 100 or rPidHighLimit ≤rPidLowLimit |

|

FilterTimeInvalid |

UDINT |

312 |

Invalid value for rDigitalFilterTime |

|

AutoTuneHysteresisInvalid |

UDINT |

313 |

Invalid value for rAutoTuneHysteresis |